Elastomeric seals serve a vital purpose in numerous dynamic and static sealing applications, even top-tier industrial polymers are susceptible to failure. These issues commonly come from wear due to friction, chemical exposure or repeated expansion and contraction in high-temperature conditions. Spring-energized PTFE seals offer a reliable, proven alternative designed specifically for such challenging environments.

What are Spring-Energized Seals?

Spring-energized PTFE seals comprise a superior PTFE sealing element distinguished by its exceptional chemical resistance, minimal friction and expansive temperature tolerance – integrated with an embedded metallic spring mechanism. This spring delivers consistent, adaptive pressure to maintain uninterrupted surface contact, compensating for progressive wear or environmental variances. Available in configurations such as O-rings, lip seals and bespoke profiles, ensure reliable leak prevention in hydraulic, pneumatic and rotary systems.

Why Select Spring-Energized PTFE Seals?

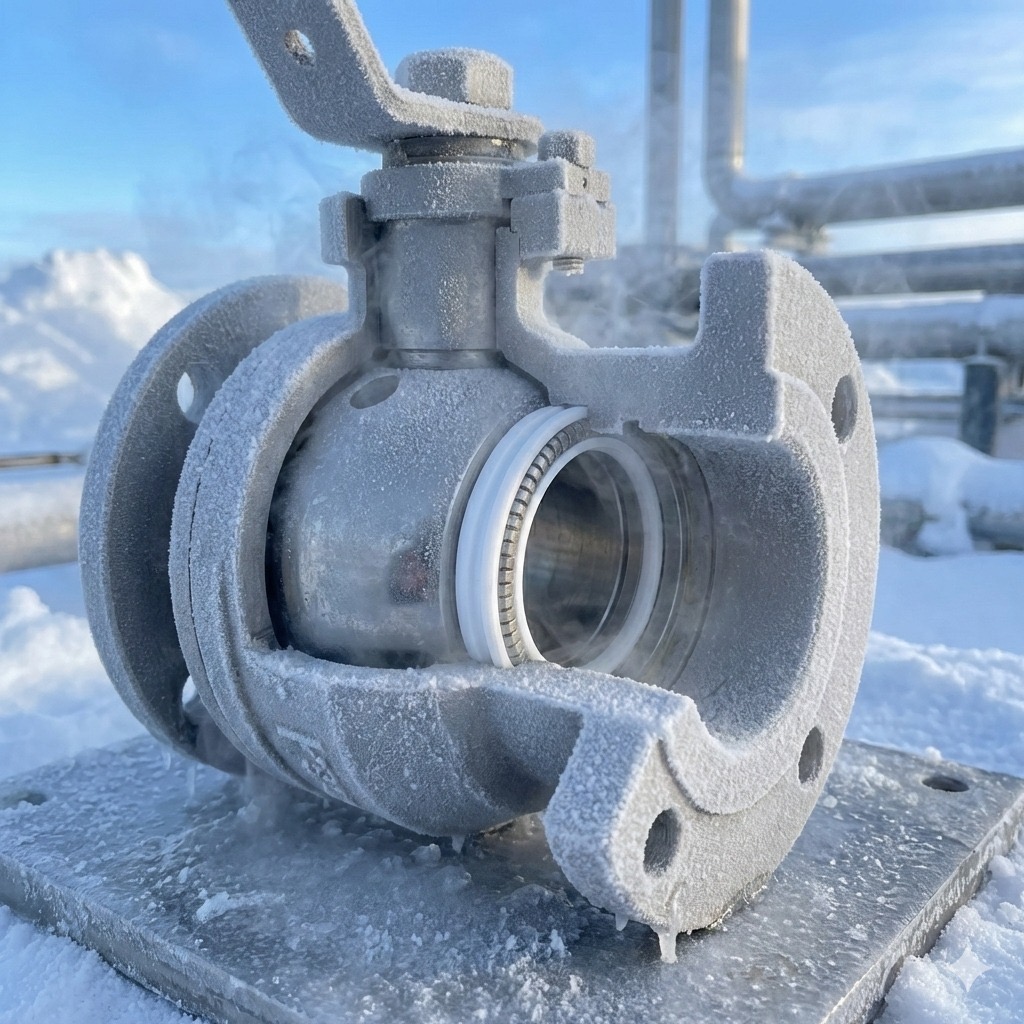

Conventional seals frequently falter under rigorous conditions, succumbing to abrasive friction, aggressive chemicals or thermal fluctuations from cryogenic lows to exceedances of 300°C—resulting in leakage, operational downtime and escalated costs. Spring-energized PTFE seals overcome these challenges by sustaining uniform, high-integrity performance where standard materials prove inadequate. This reliability renders them indispensable for key sectors including oil and gas, aerospace and chemical processing, where enhanced uptime and cost discipline directly strengthen enterprise objectives.

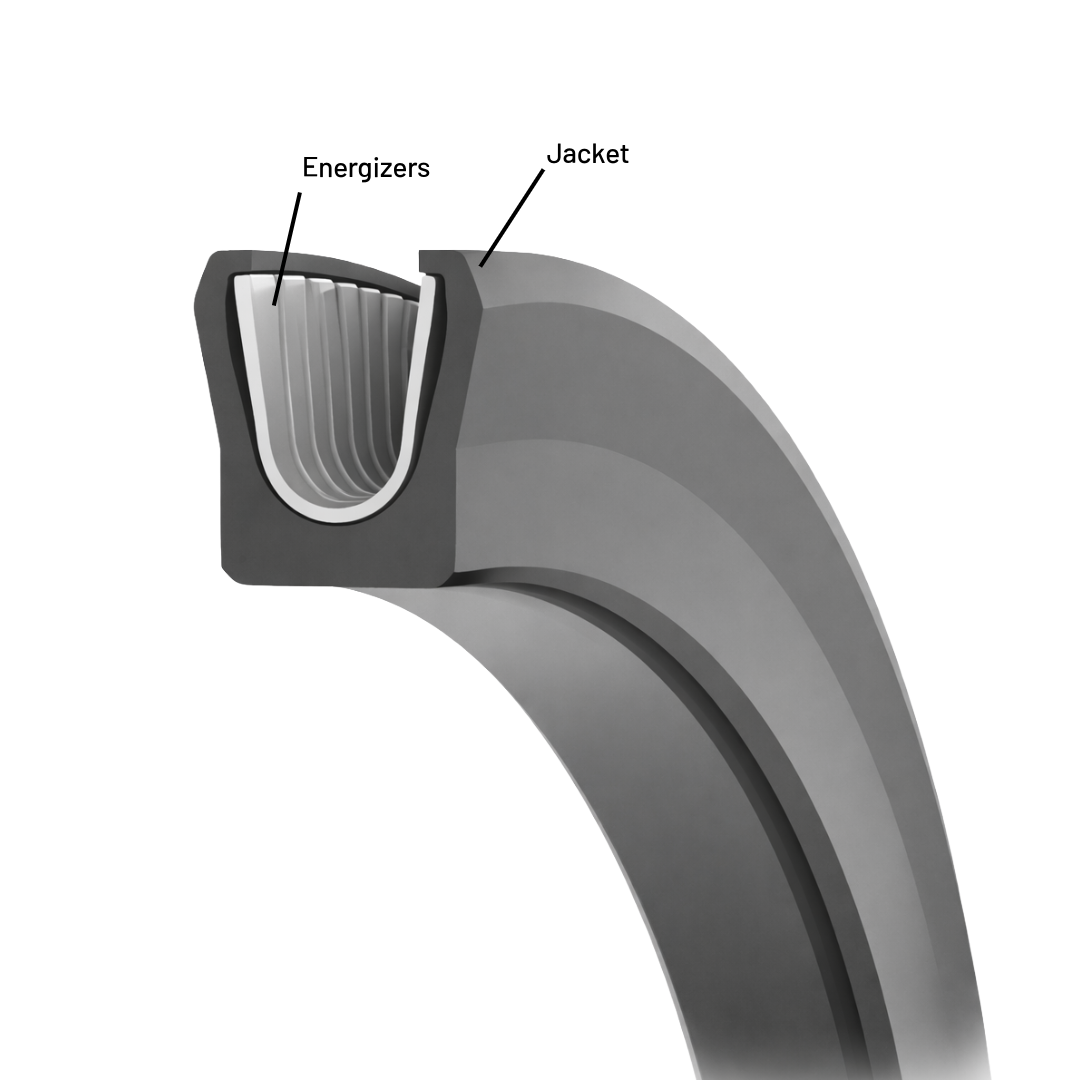

Basic Design Elements of Spring-Energized Seals

Spring-energized seals function primarily as lip seals or U-cups, constructed from high-performance elastomers, with polytetrafluoroethylene (PTFE) serving as the preferred material for the durable outer jacket. This robust polymeric jacket is reinforced by a corrosion-resistant metal spring energizer, which applies continuous force to the sealing lips, establishing a dependable gas-tight barrier across all contact interfaces.

These seals represent a strategic fusion of elastomeric and metallic sealing principles, with designs tailored to precise operational requirements. Common configurations include cantilever or V-spring profiles, ribbon or helical arrangements, U-shaped geometries and advanced pitch or coil spring variants to optimize performance under specific conditions.

Jackets

Fluoroplastic compounds and engineered plastics offer viable options for spring jackets. However, polytetrafluoroethylene (PTFE) establishes itself as the industry benchmark, distinguished by its superior durability and robust resistance to extrusion. Virgin polyetheretherketone (PEEK) finds application in backup rings and high-temperature environments, whereas formulated ultra-high-molecular-weight polyethylene (UHMW-PE) delivers value in dynamic sealing scenarios characterized by significant wear forces. The extensive adaptability of PTFE-based compounds—encompassing filled, lubricated, modified or proprietary variants ensures a tailored solution for virtually every operational requirement.

Energizers

Selection of spring energizers hinges on the chemical profile of the contained media. Stainless steels provide versatile performance with broad chemical compatibility, yet precise grade specification directly determines seal longevity. Type 301 stainless steel ranks as a prevalent choice for spring energizers, complemented by advanced alloys such as Inconel and Hastelloy for demanding corrosive conditions.

How Spring-Energized Seals Operate

Upon installation within an application cavity, a spring-energized seal undergoes radial compression, activating the spring load to drive the sealing lips firmly against the gland walls and form a robust, leak-tight barrier. This inherent radial tension ensures consistent sealing reliability from the moment of installation, independent of system pressure for effective performance. When operational pressure is applied, it further energizes the jacket, amplifying contact force and delivering superior sealing across both low- and high-pressure systems.

Spring energizers also reduce the severity of seal extrusion under elevated temperature and pressure conditions—a dynamic failure mode characterized by material nibbling or shearing during cyclic or sustained stress exposure.

Extrusion risks, however, extend beyond these factors to include extrusion gap dimensions and surface velocities. Specialized configurations, such as rectangular or triangular backup rings integrated into spring-energized seals, provide assured performance in applications prone to complex extrusion dynamics.

Require High-Performance Spring-Energized PTFE Seals?

Contact ISMAT for immediate technical consultation, application-specific compound development and production-ready seals optimized for your most critical oil & gas, chemical processing and heavy industrial sealing requirements.

Key Advantages of using ISMAT Novum PTFE Spring-Energized Seals

1) Low Friction and Wide Temperature Capability

ISMAT Novum PTFE spring-energized seals deliver ultra-low friction coefficients across an exceptional operating range of -250°C to +260°C, enabling reliable dynamic sealing in cryogenic LNG service through high-temperature steam injection. Our Novum PTFE jacket formulations provide inherent lubricity that reduces actuator energy requirements by 40-60% compared to elastomers while eliminating stick-slip in valves and pumps. Combined with the metal energizer spring’s constant radial force, these seals maintain leak-tight performance despite thermal expansion, jacket wear or pressure cycling ensuring extended mean time between failures (MTBF) and API 6A sour service compliance (10% H₂S at 200°C) across demanding industrial applications.

2) Extended Service Life and Reduced Maintenance Costs

ISMAT Novum PTFE spring-energized seals provide significantly extended service intervals compared to conventional elastomeric seals through proprietary Novum material formulations combined with continuous energizer spring force. The precision-engineered PTFE jacket resists wear, chemical degradation and thermal fatigue, while the metal spring automatically compensates for material loss—maintaining consistent sealing pressure throughout operational life. This durability translates to longer mean time between failures, minimized maintenance frequency and substantially lower total cost of ownership in critical industrial applications where equipment downtime directly impacts production revenue and operational efficiency.

3) Superior Chemical Resistance for Heavy Industrial Applications

ISMAT Novum PTFE spring-energized seals provide exceptional inertness against solvents, acids, hydrocarbons and process fluids across chemical processing, refining, pharmaceuticals and heavy machinery. The precision-engineered PTFE jacket maintains sealing integrity during prolonged chemical exposure, while the corrosion-resistant energizer ensures consistent radial force delivering extended service life and zero-leak performance where conventional elastomers fail.

Types of Spring Energized Seals Offered by ISMAT

ISMAT offers four primary spring configurations optimized for Novum PTFE spring-energized seals, each engineered for specific industrial sealing requirements:

1. V-Spring (Cantilever Spring)

High deflection capability with concentrated lip loading for reciprocating service. Optimized for subsea actuators, blowout preventers and valve applications requiring contamination exclusion and tolerance of stack-up accommodation.

2. Helical Coil Spring

Uniform force distribution for cryogenic valves, vacuum penetrations and low-cycle dynamic service requiring consistent sealing pressure across temperature extremes.

3. Garter Spring

Independent radial force unaffected by shaft length variation. Ideal for rotary equipment, downhole pumps and contaminated environments accommodating shaft runout and eccentricity.

4. slanted Coil Spring

Stable preload across varying compression and surface finishes for gate valve stems, dynamic actuators, high-cycle rotary service and misaligned offshore connections. Provides low break-out force with reliable sealing through gland tolerances.

ISMAT engineering team selects optimal spring geometry based on pressure differentials, motion characteristics, media compatibility and operational envelope to maximize seal reliability and service life across oil & gas, chemical processing and heavy industrial applications.

ISMAT Novum PTFE Materials: Technical Specifications

| Trade Name | Filler | Temp Range (°C) | Tensile (MPa) | Elongation (%) | Certifications |

|---|---|---|---|---|---|

| Novum P 01 | Virgin PTFE | -250°C to +250°C | 25 (Min) | 250 (Min) | API 6A (10% H₂S @ 200°C) |

| Novum M 03 | Modified PTFE | -150°C to +260°C | 25 (Min) | 300 (Min) | API 6A (10% H₂S @ 200°C) |

| Novum GF 01 | 15% Glass filled PTFE | -200°C to +260°C | 15 (Min) | 210 (Min) | API 6A (10% H₂S @ 200°C) |

| NOVUM GF 02 | 25% Glass Filled PTFE | -200°C to +260°C | 10 (Min) | 100 (Min) | - |

| NOVUM CF 02 | 25% Carbon filled PTFE | -200°C to +250°C | 10 (Min) | 80 (Min) | API 6A (10% H₂S @ 200°C) |

| NOVUM GC 01 | 10% Glass and 15% carbon filled PTFE | -200°C to +260°C | 10 (Min) | 100 (Min) | API 6A (10% H₂S @ 200°C) |

| NOVUM BF 01 | 40% Bronze filled PTFE | -150°C to +250°C | 14 (Min) | 160 (Min) | - |

| NOVUM CN 05 | 10% copper-nickel filled PTFE | -150°C to +260°C | 17 (Min) | 200 (Min) | - |

Why Choose ISMAT for Spring Energized PTFE Seals

ISMAT stands as the premier partner for high-performance spring energized PTFE seals, distinguished by Novum PTFE formulations engineered for extreme chemical resistance, temperature stability from cryogenic to high-temperature applications and superior mechanical properties across diverse heavy industrial applications. With decades of specialized manufacturing expertise, in-house compound development and over 4,000 production molds enabling rapid prototyping through high-volume delivery, ISMAT provides unmatched engineering support including application-specific spring geometry selection (V-spring, C-spring, helical, garter, canted coil) and custom seal profiles optimized for precise gland dimensions and operating envelopes. This technical leadership translates directly to measurable business value extended mean time between failures, minimized maintenance costs, regulatory compliance and zero unplanned downtime—positioning ISMAT as the strategic sealing partner that transforms operational reliability into competitive advantage for oil & gas, chemical processing, power generation and heavy equipment manufacturers worldwide.

Get In Touch

Contact ISMAT for Spring Energized PTFE Seals

ISMAT delivers precision-engineered spring energized PTFE seals optimized for your most demanding industrial applications.

Request engineering consultation, download Novum material specifications or submit gland dimensions for custom seal design, rapid prototyping and production-scale delivery that ensures maximum equipment reliability and minimum process downtime.

FAQs

ISMAT Novum PTFE seals operate reliably from -250°C to +260°C, covering cryogenic LNG applications through high-temperature steam service while maintaining consistent sealing performance.

ISMAT provides V-spring, C-spring, helical coil, garter and canted coil configurations, each optimized for specific motion characteristics, pressure differentials and contamination resistance requirements.

Yes, all Novum PTFE material grades demonstrate exceptional resistance to sour gas, acids, hydrocarbons and aggressive process media, ensuring reliable performance in chemically demanding environments.

ISMAT seals excel in oil & gas, chemical processing, power generation, pharmaceuticals and heavy equipment manufacturing where extended service life and zero-leak performance are mission-critical.