-

40+ YEARS OF EXCELLENCE

40+ YEARS OF EXCELLENCEin the field of high performance polymers and engineering

plastics -

PRODUCT RANGE

PRODUCT RANGEPTFE:

5 mm to 1.4 mtr

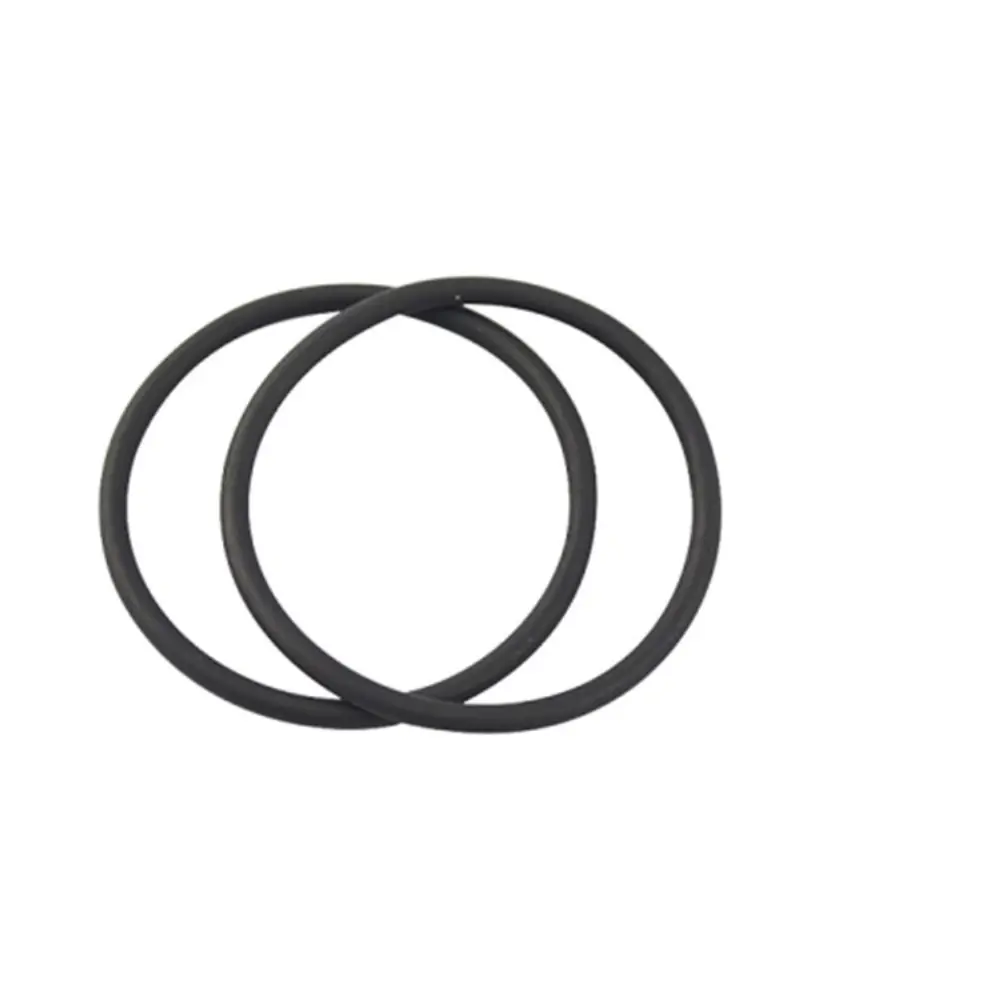

Rubber:

4 mm to 1.2 mtr -

In-house tooling

In-house tooling– Decrease lead time for prototyping.

– Increase speed to market. -

COMPOUND DEVELOPMENT

COMPOUND DEVELOPMENT– Nuclear Gamma Radiation Resistance

– Temp Range: –65°C to 320°C -

Safety stock

Safety stock– 4K+ custom moulds

– 10+ elastomers -

AED APPLICATIONS

AED APPLICATIONSISMAT Compound certified

-

OUR ACHIEVEMENTS

OUR ACHIEVEMENTS– Components developed for Harley Davidson, McLaren & ISRO

-

DEDICATED PRODUCTION FACILITY FOR FFKM

DEDICATED PRODUCTION FACILITY FOR FFKM -

FDA - APPROVED APPLICATIONS

FDA - APPROVED APPLICATIONS

Our Founder

“At ISMAT, we believe in doing business the honest and ethical way. Our commitment to excellence starts from the ground up. We secure the highest quality raw materials and ensure state-of-the-art manufacturing practices, to deliver cutting-edge products in a timely manner at the most competitive price.”

ALI HUSSAIN YAKUB (Founder)

Our vision

Trusted global partner for high performance sealing solutions, fostering growth and excellence to all.

Our MISSION

A. As the world progresses, ISMAT advances with it

developing high performance elastomer and polymer

products through cutting-edge technology.

B. ISMAT is committed to continuous innovation that delivers

only the best results for our customers.

C. ISMAT is dedicated to building long-term partnerships with

our employees and our suppliers based on integrity,

respect and mutual success.

D. Finally, ISMAT remains steadfast in making sustainable

and environmentally conscious decisions.

PRODUCTION WITH PRECISION

Our team of experts use state-of-the-art machinery at our dedicated facility to create sealing solutions that can withstand the test of time.

-

400,000 SQ.FTFACTORY AREA

400,000 SQ.FTFACTORY AREA -

250+EXPERT WORKFORCE

250+EXPERT WORKFORCE -

IN-HOUSE R&DDESIGN & TOOLING

IN-HOUSE R&DDESIGN & TOOLING

EXCELLENCE IN MANUFACTURING

- Automated Vacuum-based Compression Moulding Line

- AI-powered Injection Machines

- Advanced Auto-calibrated Preformer for Blanking

- Leading-edge

Deflashing System

(Cryogenic, Tumbling, CPM) - CNC Oscillating Rubber Cutting Machines

- Controlled Production Environment

- PLC Controlled Moulding Line

- Advanced Sintering Ovens

- High-precision CNC Machines

- Large, Automated NC Lathes

- Well-equipped Quality System

- Advanced CMM Inspection System

- Video Measurement System

- Quick Vision Measuring System

- Non-contact Measuring Gauges

Controlled Environment for Trusted Performance

With the dedicated FFKM facility at ISMAT, we ensure that our high-performance elastomers and O-ring manufacturing can deliver consistent performance with zero defects even under the most strenuous of conditions.

As a Caterpillar supplier and a member of our extended value chain, you are a critical link in our ability to fulfill our purpose of helping our customers build a better, more sustainable world. In recognition of your valued role, please accept my thanks and appreciation of your continued performance, collaboration and commitment to Caterpillar and a sustainable future.

Jim Umpleby, Chairman & Chief Executive Officer